Executive Brief

Large Class I rail yards represent one of the highest concentrations of derailment risk in the North American rail network, yet they remain among the least instrumented environments from a geometry and gauge perspective. Traditional inspection tools come in the form of geometry cars, hi-rail vehicles, and manual walking inspections, which were largely designed for mainline operations and not for the density, operational intensity, or localized degradation patterns found inside rail yards.

This paper outlines a case for deploying drone-based AI screening to identify and prioritize gauge and geometry risk in large rail yards. The approach does not replace required inspections or assert regulatory compliance. Instead, it provides management with a scalable, data-driven method to focus inspection and maintenance resources where risk is highest and does so earlier in the degradation cycle.

Strategic Context

Yards as a Disproportionate Risk Concentrator

Rail yards differ fundamentally from main line corridors:

Lower speeds but significantly higher defect density

Repetitive low-speed loading that accelerates geometry degradation

Concentrated lateral forces from humping, braking, and switching

Hundreds of short, interconnected tracks that are impractical to inspect frequently on foot

From a risk perspective, yards are not low-risk environments; they are high-risk environments with muted consequences until failure occurs. When failures do occur, the impacts include derailments, service disruption, emergency repairs, and workforce exposure.

Structural Opportunities in Existing Inspection Programs

Most Class I inspection programs exhibit the same structural limitations in yards:

Geometry cars rarely operate in yard limits

Hi-rail access is constrained or unsafe in many locations

Walking inspections are time-intensive and necessarily selective

Inspection cadence is rule-driven rather than condition-driven

These constraints create persistent blind spots precisely where risk density is highest.

Problem Statement

The core challenge is not measurement accuracy; it is prioritization.

Railroads already know how to measure gauge and geometry precisely. The unresolved issue is how to determine, across thousands of yard tracks, where to send limited inspection, maintenance, and capital resources before defects escalate into incidents.

Drone-based screening directly addresses this prioritization gap.

Solution Overview: Drone-Based Geometry Risk Screening

What the System Is

The proposed system uses low-altitude quadcopter drones equipped with high-resolution imaging and monocular AI models to conduct routine, area-based screening of yard track infrastructure.

The system identifies relative and trending indicators of geometry and gauge degradation, generating ranked risk outputs rather than pass/fail determinations.

What the System Is Not

To avoid ambiguity at the executive and regulatory level, the system does not:

Replace walking inspections

Certify compliance with FRA Part 213

Exercise protection authority

Its function is early risk identification and decision support.

Yard-Optimized Sensor Approach

The system relies primarily on:

High-resolution RGB imagery for rail-edge and gauge-face analysis

Repeatable positioning to support trend detection over time

Onboard or near-edge processing to flag anomalies efficiently

Optional three-dimensional sensing may be applied selectively in congested areas, but is not required for core value delivery.

What the System Does

The system answers management-relevant questions:

Where is gauge and geometry risk increasing?

Which tracks present the highest relative risk today?

Which locations are deteriorating faster than expected?

Where should inspectors and maintenance crews be sent first?

Typical indicators include:

Progressive gauge widening trends

Lateral rail movement and rail cant development

Tie and plate movement patterns

Fastener loss and ballast void formation

High-Value Yard Use Cases

Hump Crests and Retarder Zones

These locations experience the highest lateral loads and derailment exposure.

Routine drone screening enables early identification of degradation patterns days or weeks before they reach critical thresholds, allowing intervention during planned work windows rather than emergency response.

Classification Bowls

Large bowls may contain hundreds of tracks with uneven degradation profiles.

Drone-based area sweeps allow management to:

Compare risk across the entire bowl

Identify the top tier of highest-risk tracks

Allocate inspection and surfacing resources with precision

Switch Ladders and Leads

Switches and ladders combine high consequences with subtle geometry sensitivity.

Drone hover capability supports consistent monitoring of areas that are often visually inspected under time pressure.

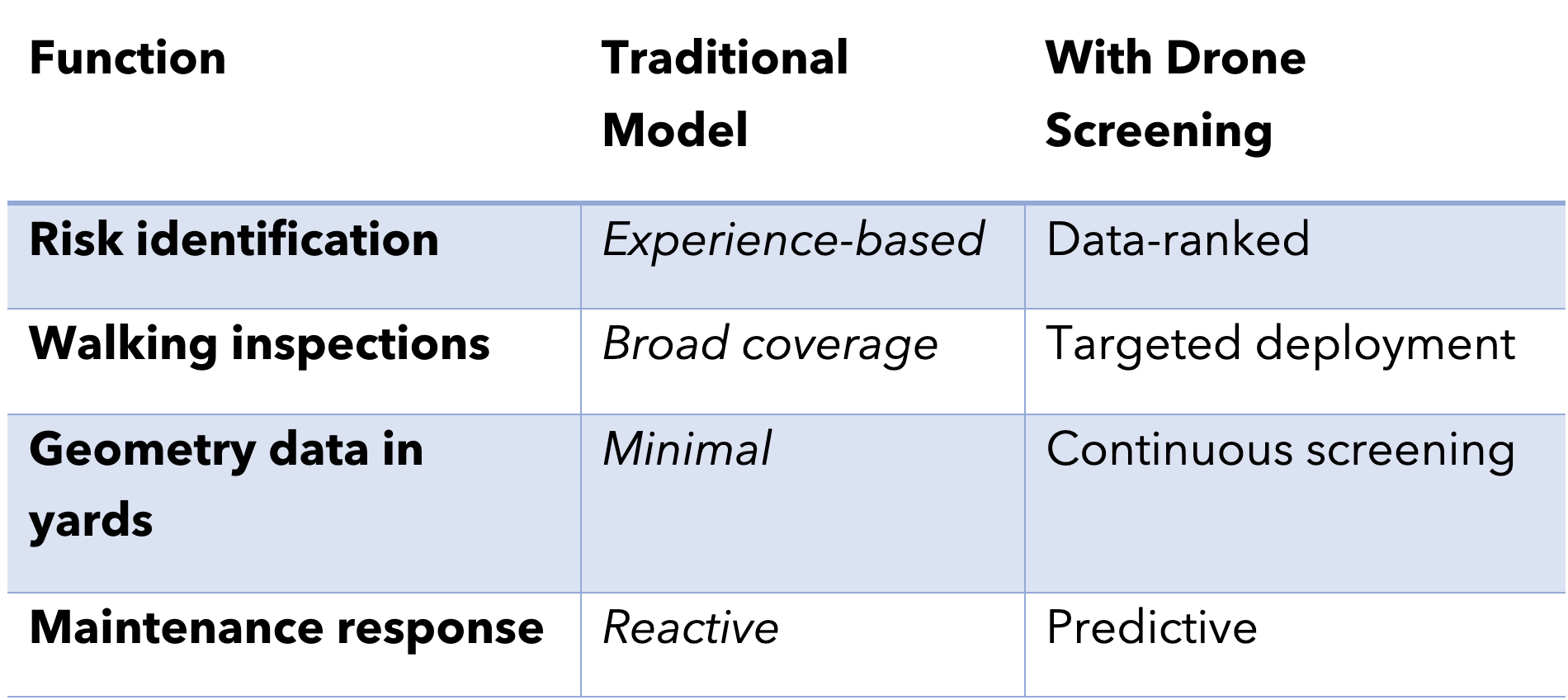

How This Changes the Inspection Model

Closed-Loop Improvement

Drone outputs guide inspections; inspection findings improve the AI models. Over time, this feedback loop increases confidence, reduces false positives, and strengthens risk forecasting.

Regulatory and Governance Alignment

From a governance perspective, the approach is deliberately conservative:

Required inspections are preserved

Human decision authority is unchanged

Technology augments detection rather than replaces judgment

This aligns with FRA and ATI principles, emphasizing hazard identification, not automation of compliance decisions.

Executive-Level Return on Investment

The value proposition is driven by risk avoidance rather than labor substitution:

Prevention of low-speed derailments with high disruption cost

Reduced emergency maintenance and outage duration

Improved safety exposure for inspection personnel

Better targeting of capital programs based on observed degradation trends

Yards amplify ROI because risk density is high and inspection inefficiency is structurally embedded.

Strategic Takeaway

Mainline inspection is about precision measurement. Yard inspection is about managing concentrated risk.

Drone-based geometry and gauge risk screening provide leadership with visibility where none effectively exists today. It transforms yards from inspection blind spots into measurable, manageable assets without increasing regulatory exposure or operational disruption.

For Class I railroads seeking measurable safety improvement with controlled deployment risk, large rail yards represent the most logical and highest impact starting point.

UNSPACE is developing Rail Genie, a marketplace which will enable the purchase of specialized railyard models, facilitate the anonymized sharing of operational data, and ultimately support a collaborative training platform for next-generation machine learning models across the rail industry.

Learn more about our models or request a free trial of Rail Genie: